In the semiconductor industry, ultraviolet germicidal lamps (especially in the UVC band) are primarily applied in critical areas such as cleanroom environment control, surface disinfection of equipment and materials, and purification of process water. Their core value lies in reducing microbial contamination through physical sterilization, thereby ensuring high yield rates in semiconductor manufacturing. The following provides a detailed analysis of specific application scenarios and technical advantages:

I. Core Application Scenarios

1. Cleanroom Environment Disinfection

Role: Semiconductor manufacturing demands extremely high cleanliness levels (e.g., ISO Class 1–5). Airborne microorganisms (such as bacteria and viruses) may adhere to wafer surfaces, causing defects and reducing yield rates.

Application Methods:

Fixed UVC Lamps: Installed on ceilings or sidewalls of cleanrooms to continuously maintain low microbial concentrations.

Mobile UVC Disinfection Carts: Used periodically to strengthen disinfection in corners, beneath equipment, and other hard-to-reach areas.

Case Study: Companies such as TSMC and SMIC employ UVC lamps in combination with HEPA filtration systems to maintain microbial concentrations at extremely low levels in cleanrooms.

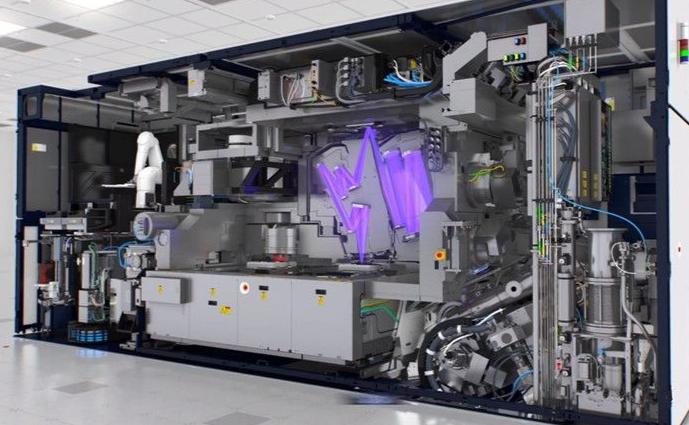

2. Equipment and Material Surface Disinfection

Role: Semiconductor equipment (e.g., lithography machines, etching tools) may accumulate microorganisms due to operator handling or environmental deposition, requiring regular disinfection to avoid cross-contamination.

(Photolithography machine)

Application Methods:

Portable UVC Flashlights: Allow simultaneous surface dust inspection and localized disinfection.

Automated UVC Modules: Integrated inside equipment to automatically initiate disinfection programs during maintenance or material replacement.

Advantages: Compared with chemical disinfectants, UVC leaves no residue and causes no corrosion, making it suitable for precision equipment.

3. Process Water Purification

Role: In semiconductor manufacturing, ultrapure water (UPW) must reach a resistivity of over 18 MΩ·cm. Microbial contamination directly compromises water quality.

Application Methods:

UVC Water Treatment Systems: Use UVC irradiation to disrupt microbial DNA in flowing water, achieving real-time disinfection.

Circulating Pipeline Disinfection: Periodically applies UVC exposure to ultrapure water pipelines to prevent biofilm formation.

Supporting Data: UVC technology can reduce microbial concentrations in process water to <1 CFU/mL, meeting SEMI standards.

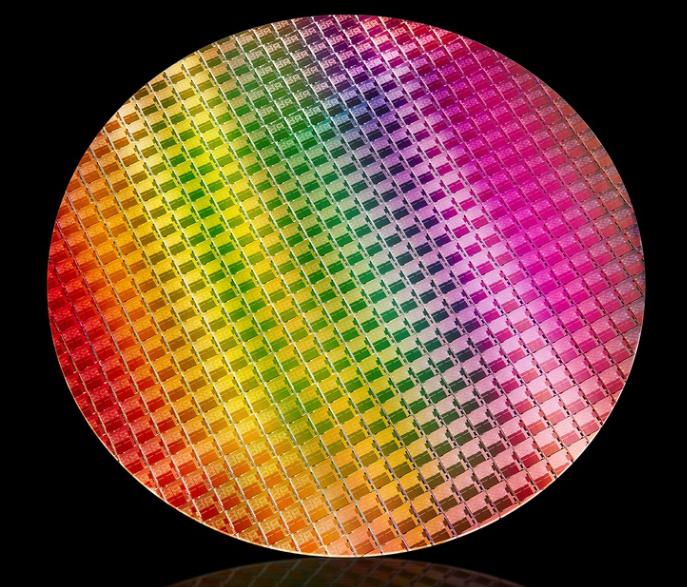

4. Wafer Surface Particle Detection Assistance

Role: During wafer dicing and cleaning, particles (including microorganisms) may remain on the surface, necessitating inspection to ensure cleanliness.

(wafe)

Application Methods:

UVC Fluorescence Detection: Certain microorganisms emit fluorescence under UVC exposure, assisting in contamination localization.

High-Power UVC Lamps: Used to excite fluorescence markers on wafer surfaces, enhancing detection sensitivity.

Effectiveness: Enables detection of particles ≥0.1 μm, significantly improving wafer yield rates.

II. Comparison of Technical Advantages

characteristic | UVC germicidal lamp | Traditional chemical disinfection | Mercury lamp disinfection |

Sterilization efficiency | Inactivate microorganisms (such as 99.99% of coronaviruses) within seconds | It requires several minutes to several hours of contact time | A certain irradiation time is required |

residue problem | No chemical residue | There may be residual disinfectant components | No residue, but it contains mercury and poses an environmental risk |

applicable scene

| Universal for multiple scenarios including air, water and surfaces | The type of disinfectant should be selected based on the material | The main focus is on air and water disinfection |

maintenance cost

| Its lifespan is over 10,000 hours | The disinfectant needs to be replaced regularly

| The lifespan is approximately 8,000 hours, and the cost of scrapping is high due to mercury content |

environmental protection property | Non-toxic and compliant with RoHS standards | Some disinfectants are harmful to the environment | Risk of mercury pollution |

III. Industry Trends and Case Studies

1.Rise of UVC-LED Technology

Advantages: Compared with traditional mercury lamps, UVC-LEDs offer compact size, non-toxicity, and instant-on capabilities, making them highly suitable for the semiconductor industry's requirements for equipment compactness and safety.

Market Data: In 2023, the global UV LED market reached USD 991 million, with UVC semiconductor products expected to achieve a CAGR of 60%.

Corporate Developments: Companies such as Sanan Optoelectronics and Refond Optoelectronics have launched UVC sterilization modules applied to semiconductor equipment disinfection.

2. Public Area Disinfection Driving Technology Upgrades

Application Expansion: Public areas in semiconductor factories, including logistics channels and changing rooms, are gradually adopting UVC disinfection robots to achieve automated, contactless sterilization.

Case Example: Ecovacs, in cooperation with Nazer Optoelectronics, has introduced mobile disinfection robots now used in public areas of semiconductor parks.

IV. Summary

The application of UV sterilization lamps, especially in the UVC spectrum, in the semiconductor industry fundamentally addresses microbial contamination through physical means. Its advantages include high efficiency, residue-free operation, and environmental friendliness, aligning closely with the industry’s stringent cleanliness requirements. As UVC-LED technology matures, its application scenarios are expected to expand further, making it a standard component of environmental control in semiconductor facilities.

Post time:2025-08-27 09:28:19