Since the WHO officially declared COVID-19 a global "pandemic" on March 11, 2020, countries around the world have unanimously regarded disinfection as the first line of defense to prevent the spread of the epidemic. More and more scientific research institutions have become very interested in ultraviolet (UV) lamp irradiation disinfection: this disinfection technology requires minimal manual operation, does not increase bacterial resistance, and can be carried out remotely without people present. Intelligent control and use are especially suitable for closed public places with high crowd density, long residence times and where cross-infection is most likely to occur. It has become the mainstream of epidemic prevention, sterilization and disinfection. To talk about the origin of ultraviolet sterilization and disinfection lamps, we have to start slowly with the discovery of the light "ultraviolet".

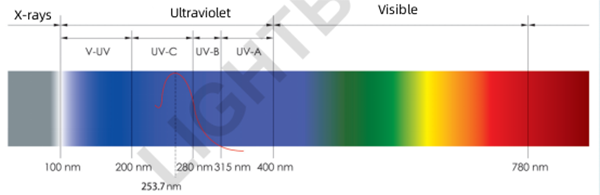

Ultraviolet rays are light with a frequency of 750THz to 30PHz in sunlight, corresponding to a wavelength of 400nm to 10nm in vacuum. Ultraviolet light has a higher frequency than visible light and cannot be seen with the naked eye. A long time ago, people didn't know it existed.

Ritter(Johann Wilhelm Ritter,(1776~1810)

After the British physicist Herschel discovered invisible heat rays, infrared rays, in 1800, adhering to the concept of physics that "things have two-level symmetry", the German physicist and chemist Johann Wilhelm Ritter,( 1776-1810), discovered in 1801 that there is invisible light beyond the violet end of the visible spectrum. He discovered that a section outside the violet end of the sunlight spectrum could sensitize photographic films containing silver bromide, thus discovering the existence of ultraviolet light. Therefore, Ritter is also known as the father of ultraviolet light.

Ultraviolet rays can be divided into UVA (wavelength 400nm to 320nm, low frequency and long wave), UVB (wavelength 320nm to 280nm, medium frequency and medium wave), UVC (wavelength 280nm to 100nm, high frequency and short wave), EUV (100nm to 10nm, ultra high frequency) 4 kind.

In 1877, Downs and Blunt reported for the first time that solar radiation can kill bacteria in culture media, which also opened the door to the research and application of ultraviolet sterilization and disinfection. In 1878, people discovered that ultraviolet rays in sunlight have a sterilizing and disinfecting effect. In 1901 and 1906, humans invented the mercury arc, an artificial ultraviolet light source, and quartz lamps with better ultraviolet light transmission properties.

In 1960, the mechanism of ultraviolet sterilization and disinfection was first confirmed. On the one hand, when microorganisms are irradiated by ultraviolet light, the deoxyribonucleic acid (DNA) in the biological cell absorbs ultraviolet photon energy, and a cyclobutyl ring forms a dimer between two adjacent thymine groups in the same chain of the DNA molecule. (thymine dimer). After the dimer is formed, the double helix structure of DNA is affected, the synthesis of RNA primers will stop at the dimer, and the replication and transcription functions of DNA are hindered. On the other hand, free radicals can be generated under ultraviolet irradiation, causing photoionization, thereby preventing microorganisms from replicating and reproducing. Cells are most sensitive to ultraviolet photons in the wavelength bands near 220nm and 260nm, and can efficiently absorb photon energy in these two bands, thereby preventing DNA replication. Most of the ultraviolet radiation with a wavelength of 200nm or shorter is absorbed in the air, so it is difficult to spread over long distances. Therefore, the main ultraviolet radiation wavelength for sterilization is concentrated between 200nm and 300nm. However, ultraviolet rays absorbed below 200nm will decompose oxygen molecules in the air and produce ozone, which will also play a role in sterilization and disinfection.

The process of luminescence through an excited discharge of mercury vapor has been known since the beginning of the 19th century: the vapor is enclosed in a glass tube, and a voltage is applied to two metal electrodes at both ends of the tube, thus creating an "arc of light" ”, making the steam glow. Since the transmittance of glass to ultraviolet was extremely low at that time, artificial ultraviolet light sources had not been realized.

In 1904, Dr. Richard Küch of Heraeus in Germany used bubble-free, high-purity quartz glass to create the first quartz ultraviolet mercury lamp, Original Hanau® Höhensonne. Küch is therefore considered the inventor of the ultraviolet mercury lamp and a pioneer in the use of artificial light sources for human irradiation in medical light therapy.

Since the first quartz ultraviolet mercury lamp appeared in 1904, people began to study its application in the field of sterilization. In 1907, improved quartz ultraviolet lamps were widely marketed as a medical treatment light source. In 1910, in Marseilles, France, the ultraviolet disinfection system was first used in the production practice of urban water supply treatment, with a daily treatment capacity of 200 m3/d. Around 1920, people began to study ultraviolet in the field of air disinfection. In 1936, people began to use ultraviolet sterilization technology in hospital operating rooms. In 1937, ultraviolet sterilization systems were first used in schools to control the spread of rubella.

In the mid-1960s, humans began to apply ultraviolet disinfection technology in urban sewage treatment. From 1965 to 1969, the Ontario Water Resources Commission in Canada conducted research and evaluation on the application of ultraviolet disinfection technology in urban sewage treatment and its impact on receiving water bodies. In 1975, Norway introduced ultraviolet disinfection, replacing chlorine disinfection with by-products. A large number of early studies were conducted on the application of ultraviolet disinfection in urban sewage treatment.

This was mainly due to the fact that scientists at that time realized that the residual chlorine in the widely used chlorination disinfection process was toxic to fish and other organisms in the receiving water body. , and it was discovered and confirmed that chemical disinfection methods such as chlorine disinfection can produce carcinogenic and genetic aberration by-products such as trihalomethanes (THMs). These findings prompted humans to seek a better disinfection method. In 1982, a Canadian company invented the world's first open-channel ultraviolet disinfection system.

In 1998, Bolton proved the effectiveness of ultraviolet light in destroying protozoa, thus promoting the application of ultraviolet disinfection technology in some large-scale urban water supply treatments. For example, between 1998 and 1999, the Vanhakaupunki and Pitkäkoski water supply plants in Helsinki, Finland, were respectively renovated and ultraviolet disinfection systems were added, with a total treatment capacity of approximately 12,000 m3/h; EL in Edmonton, Canada Smith Water Supply Plant also installed ultraviolet disinfection facilities around 2002, with a daily treatment capacity of 15,000 m3/h.

On July 25, 2023, China promulgated the national standard "Ultraviolet germicidal lamp standard number GB 19258-2003". The English standard name is: Ultraviolet germicidal lamp. On November 5, 2012, China promulgated the national standard "Cold cathode ultraviolet germicidal lamps standard number GB/T 28795-2012". The English standard name is: Cold cathode ultraviolet germicidal lamps. On December 29, 2022, China promulgated the "Energy Efficiency Limit Values and Energy Efficiency Level Standard Number of Ballasts for Gas Discharge Lamps for General Lighting: GB 17896-2022" national standard, English standard name: Minimum allowable values of energy efficiency and energy efficiency grades of ballasts for gas discharge lamps for general lighting will be implemented on January 1, 2024.

At present, ultraviolet sterilization technology has developed into a safe, reliable, efficient and environmentally friendly disinfection technology. Ultraviolet sterilization technology gradually replaces traditional chemical disinfection methods and becomes the mainstream dry disinfection technology. It has been widely used in various fields at home and abroad, such as waste gas treatment, water treatment, surface sterilization, air sterilization, etc.

Post time: Dec-08-2023